Improved lithiu-ion batteries are achieved through 3D printing

3D printing allows for faster charging and higher-energy-density lithium-ion batteries

The next generation lithium-ion batteries require greater energy and power density at economical prices. At present, conventional battery manufacturing methods are not able to further improve these vital metrics.

Meeting emissions goals and combating the climate crisis will require a concerted effort to develop new technologies — including better lithium-ion batteries.

In order to address this issue, Lawrence Livermore National Laboratory (LLNL) is teaming up with Ampcera Inc. to build solvent-free Laser Powder Bed Fusion (L-PBF) additive manufacturing technologies for the construction of 3D-structured lithium battery cathodes.

Insight on the project

The research of today will allow us to create a strong, clean energy economy for years to come. This novel project has, in fact, obtained substantial funding from the Advanced Manufacturing Office at the U.S. Department of Energy.

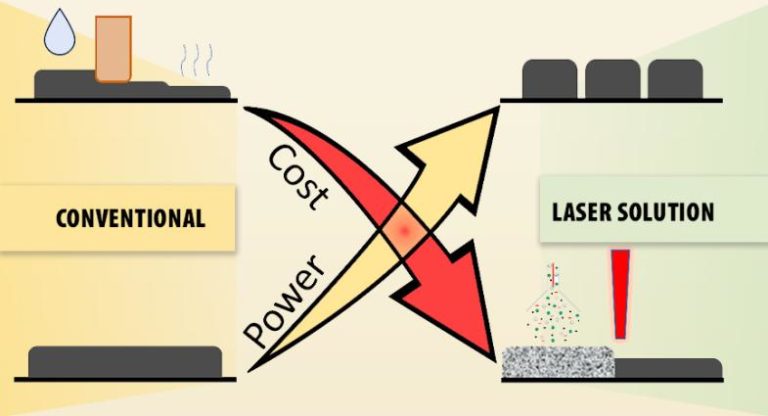

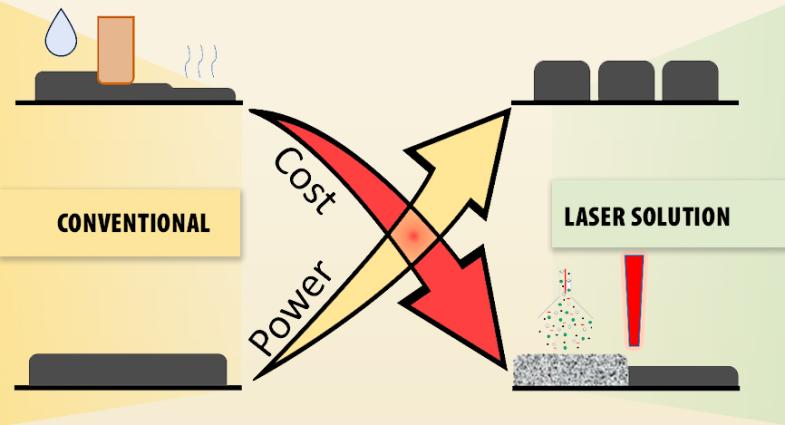

L-PBF was originally developed for 3D printing of metal parts. LLNL staff scientists are planning to use this additive manufacturing technology to thermally bind the cathode powder mixtures onto the aluminum current collector and generate unique 3D structures for faster charging and higher-energy-density batteries.

Battery charges in 15 min or less

The environmentally benign process allows for thick high-capacity 3D cathode structures to be processed, enabling lithium-ion batteries to reach the fast-charging goal of 80% charge in 15 minutes or less.

By eliminating the solvent, ultrafast laser processing allows large-scale battery manufacturing with higher production throughput, lower energy consumption and cost and likely improved power and energy densities.

Ampcera Inc. has a strong technology portfolio in high-performance solid-state electrolytes and electrode materials. Ampcera will provide state-of-the-art and highly engineered cathode powders to LLNL for L-PBF processing.

Future developments

The partnership between LLNL and Ampcera will accelerate the development and commercialization of the ultra-fast and low-cost L-PBF additive manufacturing technology for high-performance lithium battery manufacturing. After developing 3D-structured cathodes, they expect to expand the technology to anode design and also further explore its application in all-solid-state Li metal batteries with even higher energy and power densities.

sources: LLNL I Innovation News Network

cover image: LLNL

Maker Faire Rome – The European Edition has been committed since nine editions to make innovation accessible and usable to all, with the aim of not leaving anyone behind. Its blog is always updated and full of opportunities and inspiration for makers, makers, startups, SMEs and all the curious ones who wish to enrich their knowledge and expand their business, in Italy and abroad.

Follow us, subscribe to our newsletter: we promise to let just the right content for you to reach your inbox