Espositori 2022

- EDUCATION

- GAMES

- SCIENCE

- STEAM PUNK

- AEROSPACE

- DRONES

- FABRICATION

- ARTIFICIAL INTELLIGENCE

- ROBOTICS

- VIRTUAL REALITY

- NEW MANUFACTURING

- RECYCLING & UPCYCLING

- STARTUP

- ARTISANS & NEW CRAFT

- FASHION & WEARABLES

- PRODUCT DESIGN

- HOME AUTOMATION

- INTERNET OF THINGS

- WELLNESS & HEALTHCARE

- INDUSTRIAL AUTOMATION

- OPEN SOURCE

- 3D PRINTING

- ART

- ENERGY & SUSTAINABILITY

- YOUNG MAKERS (< 18)

- FOOD & AGRICULTURE

- CIRCULAR ECONOMY

- 3D SCANNING

- KIDS & EDUCATION

- CULTURAL HERITAGE

- BIOLOGY

- MUSIC & SOUND

- HACKS

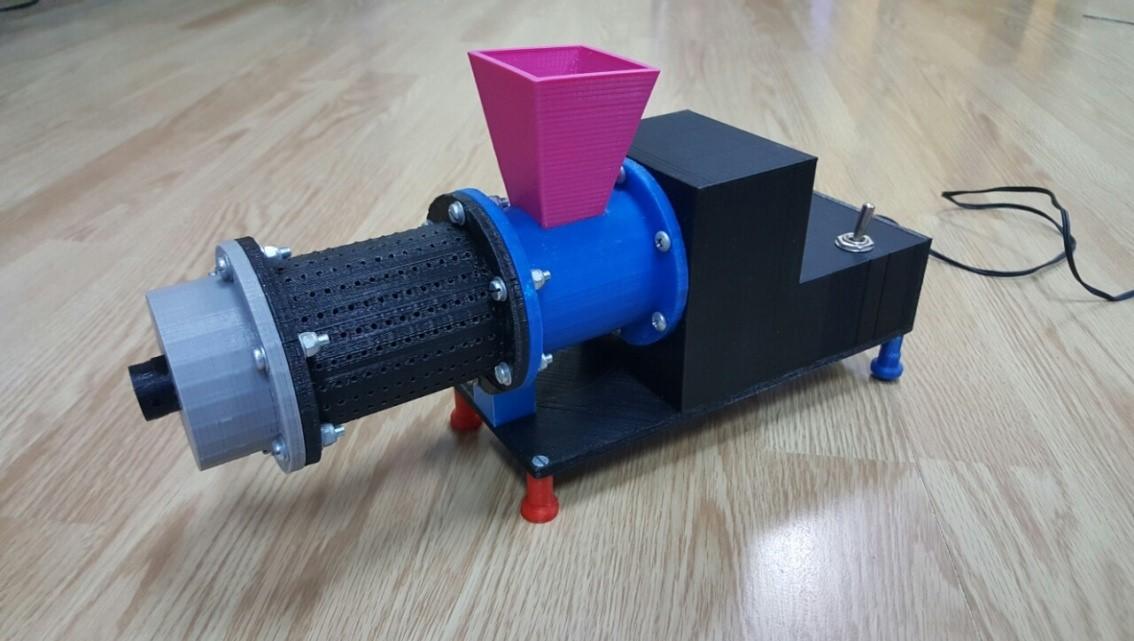

Press for cold pressing of oilseeds

The press for cold pressing of oilseeds works on the principle of compressing the mass in it body by means of a spiral-shaped shaft that pushes the mass that we press forward. Cold-pressed oil retains its high nutritional value.

The construction of this press was made using the CATIA V5 R20 program of the French company Dassault Systemes, which is intended for computer-aided design. CATIA enables: creation of 3D parts, assembly of parts into a functional whole, computer-assisted production of CAM, creation of documentation necessary for the production of an individual part.

Another program used to make the press is CURA 15.04.2 this program is intended to create a G-code from the drawn model. The G-code is used to make models on a 3D printer.

The model of the press for cold pressing of oilseeds was made on a 3D printer called Witbox 3D printer. This printer allows you to make items the size of A4 paper and 200 millimeters high, the print speed is 60 mm / s and the print quality ranges from 0.05 to 0.3 mm. PLA filament with a diameter of 1.75 mm was used to make the model.

Tehnical school, Slavonski Brod, Croatia, Mechanical computer technician, 4th grade

Antonio Tu�ek

Lovro Bogdanovi?

Project is presented by two high school students, Technical School, Slavonski Brod, Croatia. Students are 4th grade high school, occupation mechanical computer technician.