Exhibitors 2019

- 3D PRINTING

- ART

- EDUCATION

- HOME AUTOMATION

- INTERNET OF THINGS

- KIDS & EDUCATION

- RECYCLING & UPCYCLING

- ROBOTICS

- SCIENCE

- YOUNG MAKERS (< 18)

- BIOLOGY

- GAMES

- ARTIFICIAL INTELLIGENCE

- OPEN SOURCE

- NEW MANUFACTURING

- FABRICATION

- WELLNESS & HEALTHCARE

- ENERGY & SUSTAINABILITY

- FOOD & AGRICULTURE

- 3D SCANNING

- CULTURAL HERITAGE

- AEROSPACE

- HACKS

- MUSIC & SOUND

- ARTISANS & NEW CRAFT

- FASHION & WEARABLES

- DRONES

- STEAM PUNK

- ARDUINO

- CROWDFUNDING

3D LIVINGREEN (ITS 4.0)

Starting from a very traditional sector with actors often reluctant to innovation, such as construction, the project connects companies whose mission is the introduction of cutting-edge construction technologies to support energy efficiency and environmental sustainability.

The mixture of different techniques and the use of an extremely versatile production technology such as 3D printing, allows research to be progressed into materials that can be used in construction, experimenting with solutions never before considered, without neglecting cost containment.

The 3D LIVINGREEN project was born and developed in a territory, like that of Bergamo, where construction has always constituted a supporting sector and that in recent years has suffered a strong crisis, dictated not only by the more general economic crisis crossed by our Country. The objective, certainly ambitious, is to help companies in our area to change course, leading to a general rethinking of construction, at least as it has been understood so far.

The collaboration with the project partner companies is based on sharing this vision.

The project aims to give a partial answer to the need for cost containment, design efficiency and compliance with the execution times by introducing the use of 3D printing in the dry construction technique, which has as its main purposes the living comfort and energy efficiency.

The mixture of different techniques and the use of an extremely versatile production technology such as 3D printing, allows research to be progressed into materials that can be used in construction, experimenting with solutions never before considered, without neglecting cost containment.

Based on the use of dry construction technique, the team worked on replacing a component of structural layering with recycled material and inserting components made with 3D printing.

In particular, a particular complexity and laboriousness emerged in the construction and installation of curved elements in the dry system. Our team created a curved profile printed with additive technology, precisely by exploiting the freedom of form, the main feature of 3D printing.

The team has designed a 10,000 square meter campus, designed to accommodate about 300 people, designed as a technological center to be implemented with the use of dry construction technology. The architecture provides a clear prevalence of curved elements and an important use of recycled materials. The 3D printed model represents a faithful reproduction of the project realized.

The mixture of different techniques and the use of an extremely versatile production technology such as 3D printing, allows research to be progressed into materials that can be used in construction, experimenting with solutions never before considered, without neglecting cost containment.

The 3D LIVINGREEN project was born and developed in a territory, like that of Bergamo, where construction has always constituted a supporting sector and that in recent years has suffered a strong crisis, dictated not only by the more general economic crisis crossed by our Country. The objective, certainly ambitious, is to help companies in our area to change course, leading to a general rethinking of construction, at least as it has been understood so far.

The collaboration with the project partner companies is based on sharing this vision.

The project aims to give a partial answer to the need for cost containment, design efficiency and compliance with the execution times by introducing the use of 3D printing in the dry construction technique, which has as its main purposes the living comfort and energy efficiency.

The mixture of different techniques and the use of an extremely versatile production technology such as 3D printing, allows research to be progressed into materials that can be used in construction, experimenting with solutions never before considered, without neglecting cost containment.

Based on the use of dry construction technique, the team worked on replacing a component of structural layering with recycled material and inserting components made with 3D printing.

In particular, a particular complexity and laboriousness emerged in the construction and installation of curved elements in the dry system. Our team created a curved profile printed with additive technology, precisely by exploiting the freedom of form, the main feature of 3D printing.

The team has designed a 10,000 square meter campus, designed to accommodate about 300 people, designed as a technological center to be implemented with the use of dry construction technology. The architecture provides a clear prevalence of curved elements and an important use of recycled materials. The 3D printed model represents a faithful reproduction of the project realized.

Italy

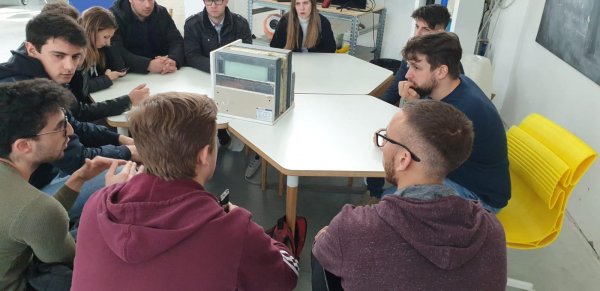

FONDAZIONE JOBSACADEMY

The JobsAcademy Foundation is a non-profit social enterprise created to educate young adults through highly specialized post-diploma technical courses. Founded in 2010, ITS Jobs Academy of the province of Bergamo has the highest number of courses and students in the national territory.

C16 (pav. 6)