Exhibitors 2015

- DRONES

- COMMERCE

- OPENING TECHNOLOGY

- ELECTRONICS

- TECHNOLOGY FOR BUSINESS

- HUMAN BODY

- MASS CUSTOMIZATION

- HEALTH

- WATER

- EXPLORING OUR WORLD

- MECHANICS

- OPEN HARDWARE BUSINESS

- TOOLS FOR MAKERS

- ART

- SPORT

- STARTUPS

- CRAFT

- ANIMALS

- SPORT & LEISURE

- HACKING DAILY LIFE

- MOBILITY

- ARCHITECTURE

- HOME AUTOMATION

- MUSIC

- MAKERS ACADEMY

- OPEN HARDWARE ELECTRONICS

- ROBOTS

- FABRICATION

- ENERGY

- INTERACTION

- FURNITURE

- AUDIO

- KIDS

- MATERIALS

- 3D PRINTING VENDORS

- RECYCLING & UPCYCLING

- EDUCATION

- HUMANOID ROBOTS

- PUPPETS

- SUSTAINABLE FUTURE

- 3D PRINTING

- DIGITAL FABRICATION

- FABLAB

- JEWELS

- CITIES

- SECURITY

- HACKING OUR SOCIETY

- ROBOTICS FOR BUSINESS

- RESEARCH

- GARDENING

- SCIENCE

- FOUNDATIONS FOR A MAKER SOCIETY

- FOOD ROBOTICS

- QUALITY OF LIFE

- FASHION & WEARABLE

- COMMUNITIES

- PHOTOGRAPHY

- MICRO AND NANO TECHNOLOGIES

- DISABILITY

- FOOD

- CROWDFUNDED PROJECTS

- COMMUNICATION

- HUMAN RELATIONSHIPS

- CULTURAL HERITAGE

- EYEWEAR

- GAMES

- CONTAMINAZIONI

- SKY & EARTH

- CLOTHING TECHNOLOGY

- FABACADEMY

- FASHION

- RETROCOMPUTING

- WEARABLE TECHNOLOGY

- BIOLOGY

- SCHOOLS

- ARTISANS

- WATCHES

- BIKES

- INTERNET OF THINGS

- 3D SCANNING

- ARTISANS & NEW CRAFT

- 3D PRINTING

- ARDUINO

- ROBOTICS

- ENERGY & SUSTAINABILITY

- OPEN SOURCE

- WELLNESS & HEALTHCARE

- FASHION & WEARABLES

- MUSIC & SOUND

- KIDS & EDUCATION

- HACKS

- FOOD & AGRICULTURE

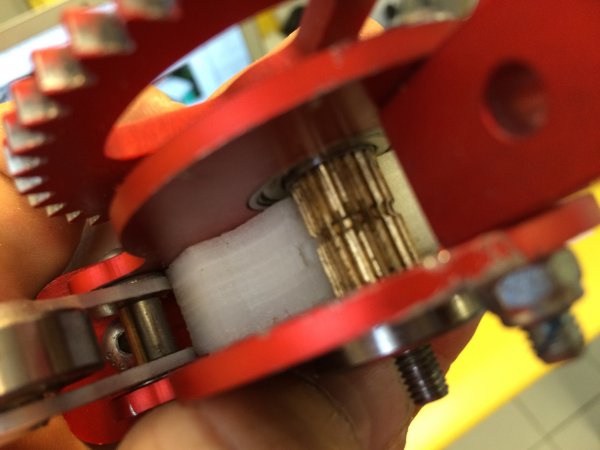

PrinterBOTtle : stampante 3D alimentata da bottiglie di PET

One big issue with low-cost 3D printers in Developing Countries is the difficulty to source filament. We try to solve this problem at the origin, by feeding the printers directly with PET plastic bottles (a quite common waste material that can be sourced easily and a very low cost both in Developed and Developing Countries). Instead of using the traditional method of washing/drying/shredding/extruding filament/printing we cut (by hand or automatically) a narrow ribbon of plastic out of PET bottles and feed it directly into a modified extruder for 3D-printing. Some issues with melting temperature/speed for PET (a thermoplastic that crystallize easily) have still to be solved in order to have a fully automatic and reliable solution.

Italy

Carlo Fonda

Carlo Fonda works for the ICTP Science Dissemination Unit. He collaborates also with technical training projects in the field of low-cost wireless communications. His interests are: coding in various languages, FabLab technologies (including 3D printers and laser cutters), web and multimedia technologies for science, applications of tablets and smartphones for research and scientific education. He's co-founder of the ICTP Scientific FabLab and co-organizer of the Trieste Mini Maker Faire.

P43