Exhibitors 2015

- DRONES

- COMMERCE

- OPENING TECHNOLOGY

- ELECTRONICS

- TECHNOLOGY FOR BUSINESS

- HUMAN BODY

- MASS CUSTOMIZATION

- HEALTH

- WATER

- EXPLORING OUR WORLD

- MECHANICS

- OPEN HARDWARE BUSINESS

- TOOLS FOR MAKERS

- ART

- SPORT

- STARTUPS

- CRAFT

- ANIMALS

- SPORT & LEISURE

- HACKING DAILY LIFE

- MOBILITY

- ARCHITECTURE

- HOME AUTOMATION

- MUSIC

- MAKERS ACADEMY

- OPEN HARDWARE ELECTRONICS

- ROBOTS

- FABRICATION

- ENERGY

- INTERACTION

- FURNITURE

- AUDIO

- KIDS

- MATERIALS

- 3D PRINTING VENDORS

- RECYCLING & UPCYCLING

- EDUCATION

- HUMANOID ROBOTS

- PUPPETS

- SUSTAINABLE FUTURE

- 3D PRINTING

- DIGITAL FABRICATION

- FABLAB

- JEWELS

- CITIES

- SECURITY

- HACKING OUR SOCIETY

- ROBOTICS FOR BUSINESS

- RESEARCH

- GARDENING

- SCIENCE

- FOUNDATIONS FOR A MAKER SOCIETY

- FOOD ROBOTICS

- QUALITY OF LIFE

- FASHION & WEARABLE

- COMMUNITIES

- PHOTOGRAPHY

- MICRO AND NANO TECHNOLOGIES

- DISABILITY

- FOOD

- CROWDFUNDED PROJECTS

- COMMUNICATION

- HUMAN RELATIONSHIPS

- CULTURAL HERITAGE

- EYEWEAR

- GAMES

- CONTAMINAZIONI

- SKY & EARTH

- CLOTHING TECHNOLOGY

- FABACADEMY

- FASHION

- RETROCOMPUTING

- WEARABLE TECHNOLOGY

- BIOLOGY

- SCHOOLS

- ARTISANS

- WATCHES

- BIKES

- INTERNET OF THINGS

- 3D SCANNING

- ARTISANS & NEW CRAFT

- 3D PRINTING

- ARDUINO

- ROBOTICS

- ENERGY & SUSTAINABILITY

- OPEN SOURCE

- WELLNESS & HEALTHCARE

- FASHION & WEARABLES

- MUSIC & SOUND

- KIDS & EDUCATION

- HACKS

- FOOD & AGRICULTURE

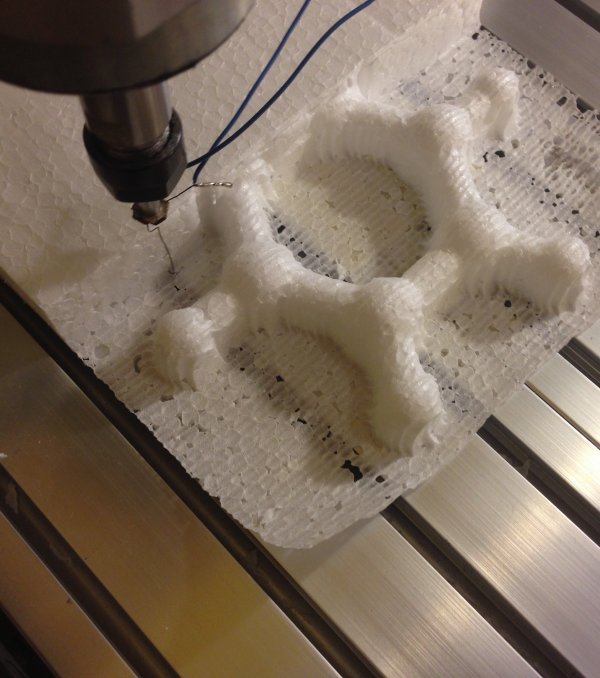

Sapienza University - PolyShaper

The PolyShaper project consists on a new technology that allows everyone to model foams, like polystyrene, with the support of CNC machines.

This technology will be the equivalent for the polystyrene which the common 3D printings were for the plastic, i.e. allow everyone its forming even in small laboratories and research centers with a very limited budget.

The core of this technology is a new tool, based on a hot wire, that reproduces the shape of a common mill tool, able to cut the polystyrene. This will allow to use a common CNC machine, CAD and CAM software and reproduce any ideas on polystyrene. At the state of art, the foams are cutted with taut hot wires and then the shape that one can realize are all parallel. With this technology instead, there are no limits on the forming possibility.

We choose, from the beginning, to maintain this project free to use and open source. We strongly believe on the open source but overall we do not want that our technology remains chained to a patent (as happened to the 3D printing that had his glory just after the expiration of the key patents). For this reason, we distribute the PolyShaper technology under the CERN Open Hardware Licence v1.2. Moreover, on the PolyShaper website, there are all the tutorials and informations needed to reproduce the tool and autonomously use it.

We are building a web platform to allow to share projects, to show to the world how people use this technology to realize their projects.

Some people can ask: why polystyrene? Well, polystyrene has many advantages with respect to other materials that are used for the CNC machining. First of all it is very chip. Still today it is often used to test CNC milling with two main problems: powder in all parts of the lab and bad quality finishing surfaces. Anyway there are many applications in which the polystyrene could be the key material, for example architectural models, molds for composite materials, decorations and many others. And our web platform will be the place where people will teach to the world how they are using the PolyShaper technology.

This technology will be the equivalent for the polystyrene which the common 3D printings were for the plastic, i.e. allow everyone its forming even in small laboratories and research centers with a very limited budget.

The core of this technology is a new tool, based on a hot wire, that reproduces the shape of a common mill tool, able to cut the polystyrene. This will allow to use a common CNC machine, CAD and CAM software and reproduce any ideas on polystyrene. At the state of art, the foams are cutted with taut hot wires and then the shape that one can realize are all parallel. With this technology instead, there are no limits on the forming possibility.

We choose, from the beginning, to maintain this project free to use and open source. We strongly believe on the open source but overall we do not want that our technology remains chained to a patent (as happened to the 3D printing that had his glory just after the expiration of the key patents). For this reason, we distribute the PolyShaper technology under the CERN Open Hardware Licence v1.2. Moreover, on the PolyShaper website, there are all the tutorials and informations needed to reproduce the tool and autonomously use it.

We are building a web platform to allow to share projects, to show to the world how people use this technology to realize their projects.

Some people can ask: why polystyrene? Well, polystyrene has many advantages with respect to other materials that are used for the CNC machining. First of all it is very chip. Still today it is often used to test CNC milling with two main problems: powder in all parts of the lab and bad quality finishing surfaces. Anyway there are many applications in which the polystyrene could be the key material, for example architectural models, molds for composite materials, decorations and many others. And our web platform will be the place where people will teach to the world how they are using the PolyShaper technology.

Italy

Carmine Gianfagna, Flavio Prattico, Francesco Riccio

Carmine Gianfagna was born on 13 August 1983 in Campobasso, Italy. He received the Master degree in MicroElectronic Engineer from the University of L'Aquila. He worked on inter-chip communication through inductive coupling in collaboration with Micron Technology. He worked on magneto-dielectric nano-materials in collaboration with the Georgia Institute of Technology and for his research he won a Best Paper Award at the 10th IEEE Nanotechnology Materials and Devices Conference (NMDC 2015), held September 13-16 in Anchorage, Alaska.

Flavio Prattico was born in Naples on November 6th 1986. He received his Master degree in Mechanical engineering at the University of L’Aquila in 2011, and, at the same university, he completed his Ph.D. on new stochastic models applied to the wind speed in 2015. He is author of more than ten paper on peer reviewed international journals and ten international proceedings. Since 2014, he has been strategic lead in research co-operation with Shibaura Institute of Technology, facilitating links between the Japanese institution and the University of L’Aquila. He is currently a research Fellow at the University of Rome La Sapienza.

Francesco Riccio was born in Naples on the 13th october 1989. After gradueting in business administration at the university of Naples Federico II refined his educational path, earning a master of science in law and business administration at Luigi Bocconi university. He had been working as auditor at PriceWaterhouseCooper, international leading company focuses on audit and assurance, tax and consulting services. Today he is involved in legal and tax consultancy in an outstanding company of the italian and international field.

Flavio Prattico was born in Naples on November 6th 1986. He received his Master degree in Mechanical engineering at the University of L’Aquila in 2011, and, at the same university, he completed his Ph.D. on new stochastic models applied to the wind speed in 2015. He is author of more than ten paper on peer reviewed international journals and ten international proceedings. Since 2014, he has been strategic lead in research co-operation with Shibaura Institute of Technology, facilitating links between the Japanese institution and the University of L’Aquila. He is currently a research Fellow at the University of Rome La Sapienza.

Francesco Riccio was born in Naples on the 13th october 1989. After gradueting in business administration at the university of Naples Federico II refined his educational path, earning a master of science in law and business administration at Luigi Bocconi university. He had been working as auditor at PriceWaterhouseCooper, international leading company focuses on audit and assurance, tax and consulting services. Today he is involved in legal and tax consultancy in an outstanding company of the italian and international field.

Padiglione Sapienza

Other project in this stand

- The LaserChat Project

- Muybridge's Revenge - Optical Toys and Paper Machines

- TIN TIN ORTO HOUSE

- FollowTheBreathe

- Sound creation and diffusion, strings to loudspeakers and opensource listening space

- Bar counter light, move!

- "Cycla" pedali in acqua a domicilio

- Glove controller

- Lampadine led RGB-W Open Source

- Lampade Plato Design

- Robot Umanoide Titanus

- Poldino un Robot per tutti

- Holey Smart Orthopedic Solutions

- BITalino - Low Cost Biomedical Toolkit

- BOTTELO HERMETIC BUCKET

- SISTEMA PER L'INTERCAMBIABILITA' DEL TACCO IN UNA CALZATURA FEMMINILE

- TRASPARENTZIA